Who made that? With 19th century Sheffield razors the most succinct answer is deeply unsatisfying. We simply don’t know.

But it has a clear manufacturer’s stamp!

And yet, the answer is the same.

While that answer is disappointing, understanding the reason why is more interesting.

Before the turn of the 19th century, and for maybe the first decade thereof, a manufacturer’s stamp had some chance of being the name or mark of the person who made the razor. With the success of the cutlery trade beginning in the mid 18th century, the workshops expanded tremendously. With bigger workshops — or wheels as they were called at the time — came more workers and a greater division of labor.

The standard jobs were:

- Forger — Most factories purchased ‘strings’ of steel from an iron monger. These were variously sized lengths created by a tilt hammer. The forger cut the strings to work-sized lengths then heated them and shaped them with a hammer. Until the Bessemer process in the early 1840’s, most steel was produced using Huntsman’s method of crucible steel in dedicated foundries. Some larger manufacturers starting with William Greaves produced their own steel, but for a long time the metal used to make razors came from only a few sources — and most of the ore came from Sweden, with some from Germany and then tiny amounts from Russia and America.

- Grinder — The most hazardous job in the factory. Between the steel and stone dust-induced silicosis (called grinders lung) and the occasional explosion of grinding wheels, this branch of the trade had a life expectancy of about 35 years. Grinders took the rough shape from the forger and ground them down to their more refined shape.

- Hafter/Setter-in — not always separate jobs. The hafter made the scales. Sometimes these were purchased from another factory. Most scales were made of some manner of horn (usually cattle or Asian water buffalo{footnote}) which had been cut into rough slabs, coated in tallow and heated in a special vise mold to create the shapes. The shapes were usually simple, but some companies specialized in highly detailed figural scales. Fancier scales were made from bone, ivory, tortoiseshell, mother of pearl — all of which could be made plainly or very fancy. The setter-in took the parts and assembled them. This entailed using thin sheets of latten (a kind of brass) to create a variety of types of washers both decorative and functional. The washers were almost always used on horn, bone, and tortoiseshell scales while ivory was usually assembled without them, using just a short piece of brass that was peened over. The setter-in would also typically ‘set’ or hone the razor for use. ‘Set and Ready to Use’ was a common etching on blades.

- Polisher — The polishing of the blade was the lowest rung on the ladder. It was typically a job for apprentices and in practice was often done by children. That does not mean it wasn’t dangerous. There were numerous names for the types of finish on Sheffield razors. A glaze would be effectively unpolished, or as it came from the finest grade grinding stone. A crocus finish was done with the finest grade of iron oxide powder mixed with beeswax and coated onto a leather-wrapped wooden wheel.

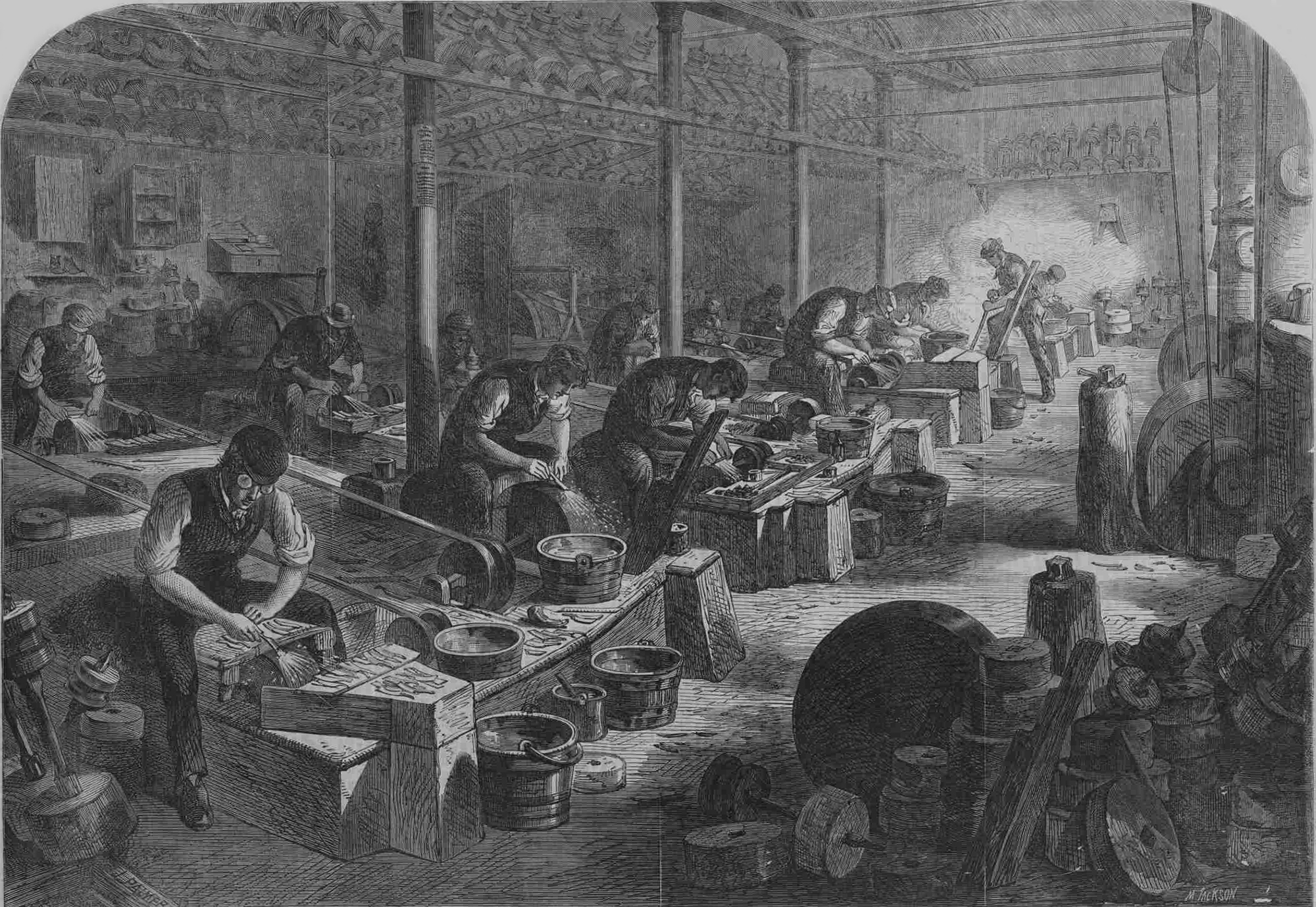

A typical Sheffield workshop, showing razors being ground on a variety of stones. Image from {where the hell is it from, other than a newspaper?}

These workers were overseen by a Little Master, or Little M’ester in the Sheffield patois. Little Masters were workmen so had completed an apprenticeship and were trained in all the parts of the trade.

Little Masters were responsible for the bulk of the work that was produced in the Sheffield factory system from about 1815 up until machine production began taking over in the late 1800’s. They hired teams of workers to make the actual products. They oversaw production.

We tend to imagine factories turning out stockpiles of goods that are stuck in a warehouse then sold. The system then, however, was much more hand-to-mouth. Goods were made as orders came in. Manufacturing firms had salesmen who traveled around the world to collect orders from shops of all sorts (bookstores and stationers sold razors through much of the first half of the 19th century, because quills were the most popular writing implement and you needed a pen-knife to use them).

The difficulty for everyone was that it cost money to maintain a workshop or wheel. To offset that, the Little Masters paid rent on their space in the factory, they paid for gas light, for tools, even for the materials used to make goods for their employer. It was common for a Little Master to work at two, three, or more firms simultaneously in order to not only pay bills but also make money. Adding to the difficulty, some firms insisted in paying partly or wholly in truck, an archaic term for goods the Little Master was expected to sell, be that coffee or cheap cutlery (sometimes made illegally from iron dressed as steel).

When a firm didn’t have enough orders, Little Masters took work orders from other firms, meaning a razor stamped with Marshes & Shepherd could have been made in the factory of William & Samuel Butcher, or Edward Allison, or Joseph Cam or, really, any name you could mention from the time. For many years Joseph Elliot’s factory space was spread across numerous workshops owned by other manufacturers.

It’s this that makes it impossible to know “who made that?”. Razors with generic stamps like ‘Refined Steel’ or ‘Warranted’ would have likely been made by Little Masters paying their bills.

The workers said they could identify the work of individual Little Masters by characteristic elements of design or marks, but that knowledge is all lost now, as are the names of most of the Little Masters.

{footnotes}

— cattle horn, unless it was unusually beautifully patterned would be dyed or bleached depending on the intended final form